Roto Pumps offers fuel transfer pumps (oil pumps) that are suitable for an entire range of upstream, midstream, and downstream applications for oil and gas industry applications. Roto Pumps, oil pumps are available in vertical and horizontal design and can effortlessly transfer high viscous, shear sensitive, and abrasive liquids.

Exploration and production of oil

Crude oil is a combination of over 200 hydro carbon compounds found in between the layers of sedimentary rocks under the surface of ground and ocean floor.

Despite its utility in multiple sectors and popularity as fuel source; the process of exploration, processing, refining and supply of crude oil and its derivatives is an extremely complex and cost intensive process

Once a potential accumulation of crude has been discovered and its commercial viability is determined, process of drilling begins.

Drilling is performed by assembling a drilling rig on the surface. Drill bit and a series of components are combined to form drill string that is used to dig a hole in the surface that is deep enough to reach the crude oil reserves. Throughout the process of drilling, a drilling fluid is circulated through the drill string to

- Lift off the cuttings of rocks and bring them to surface

- Cool drilling bit and lubricate drilling pipes

- To prevent the hole from caving in, especially in areas where extreme pressure difference exist between surface and rock layers

After initial drilling and confirmation of the presence crude oil reserve, Hole is cemented to eliminate any chances of caving in and commercial production of crude oil begins.

For this a steel casing is cemented in place and surface facilities are installed for collection and transfer of crude oil.

Perforation is the next step after installation of metallic casing; both horizontal and vertical perforation can be done to maximize the production of crude oil.

Due to a pressure difference between the formation and bottom hole, oil begins flowing from the rocks and travel to the surface. When oil stops flowing of its own accord; a technique called Enhanced Oil Recovery (EOR) is used to flush out crude oil trapped in rock capillaries. EOR can increase the production of crude oil by up to 70 % from a particular oil well.

Generally oil fields stretch over a large area and multiple oil are drilled in close proximity of one another. Here the crude oil is collected in a common field gathering facility before being transferred for refining When no more oil can be produced from the well, the hole is closed with cement and abandoned.

Roto Pumps are preferred pump for EOR and Field Gathering and are used by biggest oil players in all processes of oil production this includes exploration, production, transportation, refining, distribution and supply.

EXPLORATION

WELL SERVICES

- Drilling mud transfer

- Decanter centrifuge feeding

- Oily mud transfer

- Waste management

ENHANCED OIL RECOVERY

- Water injection

- Polymer transfer

- Surfactant transfer

FRACKING

- Viscous liquids with suspension solids

- Shear-sensitive media

- Crude oil with suspended solids

REFINING

REFINERY & PETROCHEMICAL

- Vacuum residue

- Visbreaker feed

- Catalytic reforming unit feed

- Delayed coker unit feel

- Catalyst slurry

- Bitumen

- Asphalt

- Black oils

- White oils

- Industrial fuel oil

- Lubricating oil

- Slop oil

- Sludge transfer

- Oily water treatment

PRODUCTION

OIL & GAS PROCESSING

- Open & closed drains transfer

- Flare KO drum emptying

- Crude oil transfer

- Hydrocarbon condensate transfer

- Rich MEG/Glycol reclamation

- Hydrocarbon sludge

PRODUCED WATER MANAGEMENT

- Produced water treatment

- Skimmed oil transfer

DISTRIBUTION

STORAGE AND DISTRIBUTION

- Crude oil transfer

- Tank stripping

- Oily sludge

- Railway wagon unloading

- Road tanker uploading

- Export pumps

- Sump emptying

- Slop oil

- Bitumen

- Asphalt

- White oils

- Black oils

- Ship loading & unloading

TRANSPORTATION

TRANFER SERVICES

Crude oil transfer from group gathering stations to processing units through pipelines.

CONSUMER

PETROL DISPENSING UNITS

- Lubricating oil

PIONEERING SOLUTIONS THAT DELIVER SUCCESS

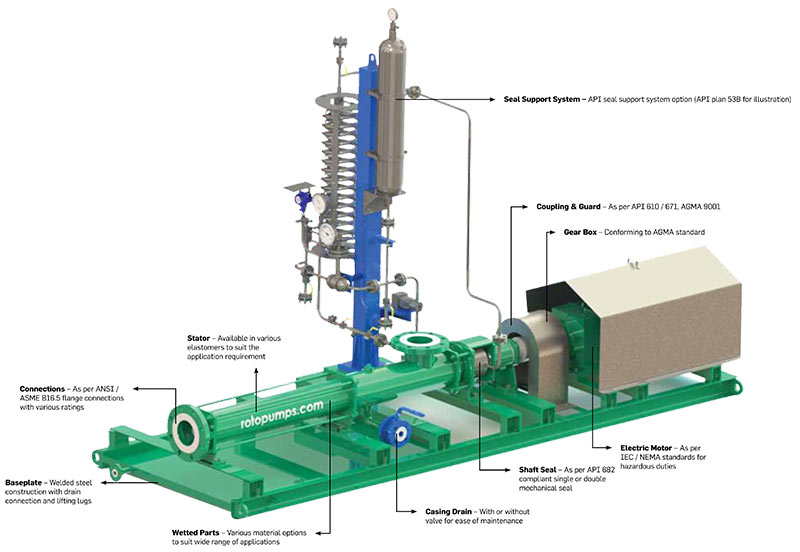

Progressive cavity pumps.

Distinctive design, features & benefits.

Positive displacement: Head developed is independent of speed , and capacity is approximately proportional to sleep.

Low NPSHR: Ensures smooth operation with high temperature and high vapor pressure liquids.

Self-priming: Can work on gaseous liquids, does not require a foot valve up to to 9.5 mwc and is effective even in high vacuum conditions.

Low internal velocity: Ensures minimum degradation of shear sensitive media.

Non–clogging : Can handle high percentage of solids in suspension.

Ideal for multi phase pumping: Can handle oil, water, gas, solids & combination together

Versatile across viscosity range: Can handle all kinds of liquids from water to liquids with very high viscosity.

Smooth and non-pulsating flow : No need of pulsation dampners.

PERFORMANCE SUMMARY

Maximum flow rate – 420m2/hr/1850 US gpm

Maximum Differential pressure – 72 bar/1045 psi

Maximum fluid temperature – 150 C / 302 F

DELIIVERING HIGH PERFORMANCE AND RESULTS.

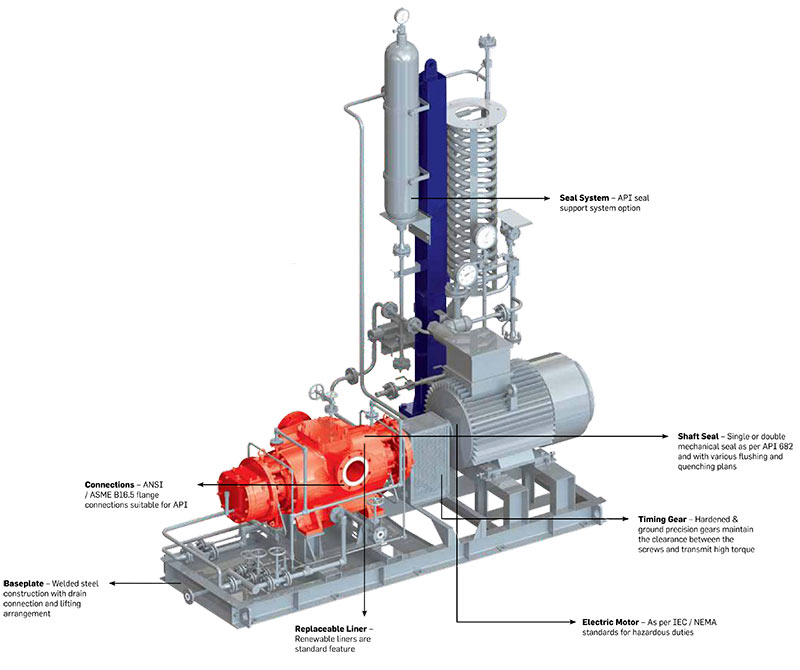

Twin screw pumps

Distinctive Design , features & benefits.

Long & trouble free service life: due to absence of metal-to-metal contact between the pumping elements & housing,

The pump can even run dry for limited period of time.

Uniform metered flow: being a positive displacement pump, head developed is independent of speed , and capacity is approximately proportional to speed

No axial thrust: dual flow of liquid in opposite direction balancers axial thrust

Capable of handling wide variety of fluids: Clear lubricating /non lubricating as aggressive liquids can be handled due to choice of different designs and materials.

Higher volumetric efficiency: Due to special double profile of screw flanks

High cavitation-free suction lift: due to low NPSH.

Safe to operate : Has in-built relief valve designed to by pass up to 100% capacity.

Wider conformity to API 676, 3rd edition.

PERFORMANCE SUMMARY

Maximum flow rate- 1000m2/hr/4402 US gpm

MAXIMUM DIFFERENTIAL PRESSURE – 40 bar/ 580pal

Maximum fluid temperature- 150 C/662 F

Engineered solution for closed/open drain oil vessels.

Mixture of produces water,oil and solids are channelized into closed or open drains to avoid harmful effects to the environment. Due to very low NPSH requirement , variable viscosities and shear sensitivity of the product , conventional pumps are not suitable.

ROTO semi-submersible pumps

Roto semi-submersible pumps are self-priming and are capable of handling solids , liquids and gases all put together.

We offer best in class designs when it comes to customized pumps for closed/open drain oil & KO drum applications.

These pumps are custom designed for various sump depths up to 10 meters.

Vacuum residue

The highly viscous fractionated atmospheric residue is transported from the atmospheric distillation tower (ADU) to the vacuum distillation tower (VDU). Due to very low pressure, heavy materials are vaporized temperatures under cracking conditions. High amount of light & middle ractions of gas oils , fuel oils and a residue (Vacuum Bottoms) are removed from the fluids, resulting in increase of viscosity of vacuum residue in feedstock. A twin screw pump is used at the location.

Roto twin screw pumps

Roto twin screw pumps can handle the highly viscous residual fluid even at the elevated process temperatures and are capable dealing with low NPSH conditions due to the high vapor pressure of the process steam.

Material of construction

Material of construction can vary from carbon steel to exotic materials like duplex, Super Dulex , and Inconel etc. these pumps are fitted with mechanical seals as per API682 with customized API seal support system as per the specifications. The coupling between the drive motor & pumps are conforming to API 610/671/AGMA 9001.

| APPLICATION AREAS | PUMP TYPE | |||

|---|---|---|---|---|

| RM | RL | RD | RJ | |

| Calcium cup grease | √ | √ | √ | |

| Catalyst injection | √ | √ | √ | √ |

| Coagulators | √ | √ | √ | √ |

| Condensates | √ | √ | √ | |

| Crude oil & water transfer | √ | √ | √ | |

| Crude oil heavy | √ | √ | √ | |

| Cutting oil | √ | √ | √ | |

| Diesel fuel, fuel oil / heavy oil | √ | √ | √ | |

| Drilling mud | √ | √ | √ | |

| Fire extinguishing agent | √ | √ | √ | |

| Grey / black water | √ | √ | √ | |

| Kerosene / gasoline | √ | √ | √ | |

| Lubricants | √ | √ | √ | |

| MEG / TEG slurry | √ | √ | √ | |

| Multiphase fluid transfer | √ | √ | √ | |

| Offshore oil transfer | √ | √ | √ | |

| Oil & wax mixture | √ | √ | √ | |

| Oil sludge, skimming, waste | √ | √ | √ | |

| Open / closed drains – KO drums | √ | √ | √ | |

| Paraffin / wax | √ | √ | √ | |

| Polymer flooding | √ | √ | √ | √ |

| Polymer transfer | √ | √ | √ | |

| Produced water | √ | √ | √ | |

| Re-injection / salt water injection | √ | √ | √ | |

| Sea water | √ | √ | √ | |

| Skimmer oil from API | √ | √ | √ | |

| Slop / waste / reject oil | √ | √ | √ | |

| Tar/ wax | √ | √ | √ | |